A Comprehensive Guide to Choosing Pallet Rack Frames and Beams

Selecting the right pallet rack frames and beams is crucial for creating an efficient and organized storage system. Whether you’re expanding existing racking or starting from scratch, understanding your space restrictions, pallet utilization, and weight capacity requirements is essential. In this blog post, we will provide you with valuable insights and tips on how to choose the ideal pallet rack frames and beams for your specific needs.

How to Choose Pallet Rack Frames:

- Consider Your Space Restrictions: Before selecting pallet rack frames, measure your available space, starting with the ceiling height. For smaller layouts like sheds or personal garages, frames ranging from 8 to 12 feet tall are commonly used. Knowing your ceiling height will help determine the maximum height you can store your products.

- Account for Pallet Usage: Pallet rack systems are designed to store products arranged on pallets. If you are using standard pallets (40″ wide by 48″ deep), racking manufacturers typically recommend 42″ deep frames. This allows for a 3″ overhang on the front and rear of the system, providing ample support for forklift operators to rest the pallets on both beams.

- Determine Weight Capacity: Understanding the weight capacity of your frames is crucial. Most manufacturers list weight capacity assuming 48″ beam spacing. However, if you plan to use spacing different from the standard, it’s important to consider the impact on weight capacity. Ensure your frame capacity meets your specific requirements to maintain a safe and reliable storage solution.

How to Choose Pallet Rack Beams:

- Assess Pallet Quantity per Shelf Level: To determine the appropriate beam length, consider how many pallets you intend to place on each shelf level. For a two-pallet per level setup, 8-foot beams are generally sufficient. If you aim to accommodate three pallets per shelf level, 12-foot beams are recommended. Measure the distance between your frames to determine the correct beam length.

- Evaluate Weight Capacity for Beams: Similar to frame selection, it’s vital to consider the weight capacity of your beams. Longer beams have a higher risk of sagging if weight distribution is uneven. Ensuring even weight distribution is crucial to prevent system failure. The height of the beam face also impacts its capacity to support weight. Choose beam lengths and face sizes that align with your specific capacity requirements.

Choosing the right pallet rack frames and beams is essential for maximizing storage space and maintaining a safe working environment. By considering factors such as space restrictions, pallet utilization, and weight capacity, you can make informed decisions that align with your storage needs. Remember to consult with experts or reputable suppliers to ensure you select the most suitable pallet rack frames and beams for your application.

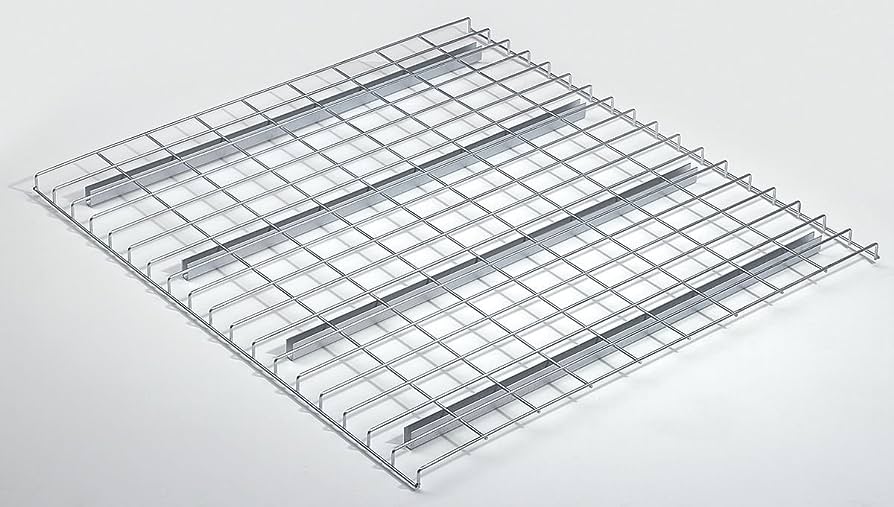

Enhancing Industrial Storage Efficiency with Wire Decking for Racking

Enhancing Industrial Storage Efficiency with Wire Decking for Racking In the world of industrial storage, optimizing space and ensuring safety are...

Read MoreMaximizing Efficiency: The Top 10 Advantages of Having an Organized Warehouse

Maximizing Efficiency: The Top 10 Advantages of Having an Organized Warehouse In the fast-paced world of logistics and supply chain management,...

Read More