Understanding Roll Formed Steel vs Structural Steel

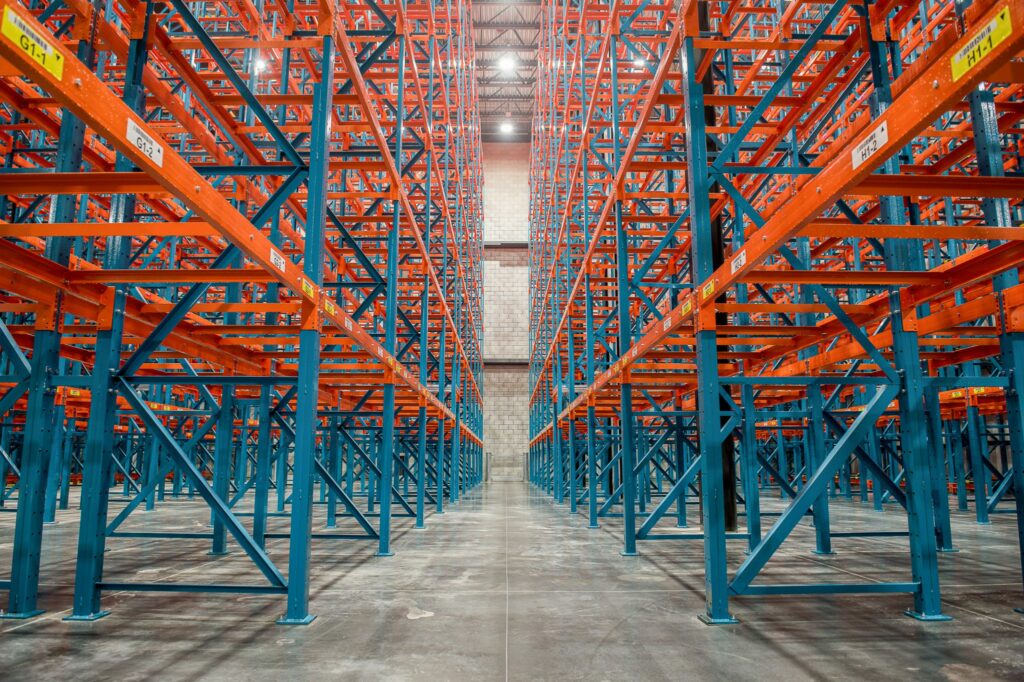

In the world of warehouse storage solutions, pallet racks and cantilever racks play a pivotal role. The efficiency, durability, and capacity of these racks are greatly influenced by the type of steel used in their construction. The most common types of steel used are roll formed steel and structural steel. Understanding the differences between these two materials is crucial for making informed decisions about storage solutions.

What is Roll Formed Steel?

Roll formed steel is manufactured by progressively shaping a metal strip into a desired profile through a series of roll stands. Each stand bends the strip slightly more than the previous one. This process results in a product with a uniform cross-section. The advantages of roll formed steel include:

- Cost-Effectiveness: Roll forming is an efficient production process, making roll formed steel generally more cost-effective than structural steel.

- Versatility: It allows for a high degree of design flexibility and can produce a wide range of shapes and sizes.

- Weight: Roll formed components are often lighter than their structural steel counterparts.

What is Structural Steel?

Structural steel is made by molding steel into predetermined shapes and sizes, typically using hot rolled or cold formed methods. It is known for its strength and durability. Key characteristics include:

- Strength: Structural steel has a higher strength-to-weight ratio compared to roll formed steel.

- Durability: It is more resistant to impact and heavy loads, making it suitable for environments with high stress or heavy wear.

- Customization: While not as versatile as roll formed steel in terms of shapes, structural steel can be customized to meet specific strength requirements.

Comparison in Application

When it comes to pallet racks and cantilever racks, the choice between roll formed and structural steel depends on various factors:

- Load Capacity: Structural steel is preferred for heavy-duty applications due to its superior strength. For instance, a standard structural steel pallet rack can hold more weight compared to a roll formed steel rack.

- Cost Considerations: For businesses looking for a cost-effective solution, roll formed steel racks offer a balance between performance and price.

- Flexibility and Adaptability: Roll formed steel racks are often easier to adapt and reconfigure, making them suitable for businesses with changing storage needs.

- Durability and Maintenance: Structural steel racks are more resilient in harsh conditions and require less maintenance over time.

According to industry reports, roll formed steel racks can reduce costs by up to 25% compared to structural steel racks. However, structural steel racks have a longer lifespan and can handle approximately 20-30% more weight under similar conditions.

Choosing between roll formed steel and structural steel for pallet and cantilever racks depends on the specific needs of the warehouse, including budget, load requirements, and environmental conditions. While roll formed steel offers cost efficiency and flexibility, structural steel stands out for its strength and durability. A comprehensive evaluation of these factors will guide you to the best choice for your storage requirements.

Understanding Roll Formed Steel vs Structural Steel

Understanding Roll Formed Steel vs Structural Steel In the world of warehouse storage solutions, pallet racks and cantilever racks play a...

Read MoreExploring the Versatility of Cantilever Racks in Industrial Storage

Exploring The Versatility of Cantilever Racking In Industrial Storage In the dynamic landscape of modern industry, the organization and storage of...

Read More